尺寸

型 號 | A | L | W | E | F | G | M | 螺栓鎖緊扭矩 (N· m) |

XBWS-15C2A | 15 | 7.5 | 22 | 6.1 | 2.3 | 5.25 | M2 | 0.5 |

XBWS-19C2A | 19 | 9 | 25.5 | 8.5 | 2.5 | 7.1 | M2 | 0.5 |

XBWS-25C2A | 25 | 11 | 32.2 | 12.5 | 3.5 | 9.25 | M2.5 | 1 |

XBWS-27C2A | 27 | 11 | 32.2 | 14.5 | 3.5 | 10.25 | M2.5 | 1 |

XBWS-34C3A | 34 | 12 | 37.4 | 16.5 | 4 | 13 | M3 | 1.5 |

XBWS-39C2A | 39 | 15 | 46.6 | 20.5 | 5 | 14.5 | M4 | 3.5 |

XBWS-44C2A | 44 | 15 | 46.6 | 23 | 5 | 17 | M4 | 3.5 |

XBWS-56C3A | 56 | 20 | 60.4 | 29 | 6 | 21.25 | M5 | 8 |

型號 | 標準孔徑 D1-D2 | |||||||||||||||||

3 | 4 | 5 | 6 | 8 | 10 | 11 | 12 | 14 | 15 | 16 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | |

XBWS-15C2A | ● | ● | ● | ● |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

XBWS-19C2A |

| ● | ● | ● | ● |

|

|

|

|

|

|

|

|

|

|

|

|

|

XBWS-25C2A |

|

| ● | ● | ● | ● | ● | ● |

|

|

|

|

|

|

|

|

|

|

XBWS-27C2A |

|

|

| ● | ● | ● | ● | ● | ● |

|

|

|

|

|

|

|

|

|

XBWS-34C3A |

|

|

| ● | ● | ● | ● | ● | ● | ● | ● |

|

|

|

|

|

|

|

XBWS-39C2A |

|

|

|

| ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

|

|

|

|

XBWS-44C2A |

|

|

|

| ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

|

|

|

XBWS-56C3A |

|

|

|

|

| ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

● 所有產品皆附有內六角螺栓。

● 軸心公差建議為h6或h7。

● 安裝到D Cut時,請注意軸的D Cut面位置。

性能

型號 | 最大孔徑 (mm) | 常用扭矩*1 (N· m) | 最大扭矩*1 (N· m) | 最大轉速 (min-1) | 慣性力矩*2 (kg· m2) | 靜態扭轉剛性 (N · m/rad) | 偏心 (mm) | 偏角 (°) | 軸向偏差 (mm) | 質量*2 (g) |

XBWS-15C2A | 6 | 0.5 | 1 | 42000 | 5.0×10-7 | 300 | 0.05 | 1 | ±0.2 | 20 |

XBWS-19C2A | 8 | 1 | 2 | 33000 | 1.6×10-6 | 550 | 0.15 | 2 | ±0.2 | 38 |

XBWS-25C2A | 12 | 1.2 | 2.4 | 25000 | 6.1×10-6 | 1100 | 0.2 | 2 | ±0.4 | 71 |

XBWS-27C2A | 14 | 1.5 | 3 | 23000 | 8.2×10-6 | 1300 | 0.2 | 2 | ±0.4 | 88 |

XBWS-34C3A | 16 | 3.5 | 7 | 18000 | 2.5×10-5 | 1800 | 0.25 | 2 | ±0.6 | 160 |

XBWS-39C2A | 20 | 5 | 10 | 16000 | 5.1×10-5 | 3500 | 0.3 | 2 | ±0.6 | 260 |

XBWS-44C2A | 22 | 7 | 14 | 14000 | 8.9×10-5 | 5500 | 0.3 | 2 | ±0.6 | 400 |

XBWS-56C3A | 28 | 15 | 30 | 11000 | 2.9×10-4 | 10000 | 0.3 | 2 | ±0.8 | 800 |

*1 無須根據負荷變化修正常用扭矩和最大扭矩。

*2 最大孔徑時的數值。

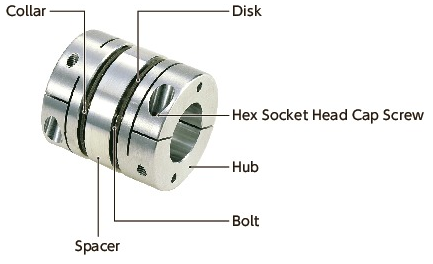

構造

●挾持型

XBWS-C 全不鏽鋼製

材質、表面處理 ![]() 符合環保標準

符合環保標準

| XBW-C | XBWS-C |

軸套 | A7075* | SUS303 |

間隔塊 | A7075* | SUS303 |

螺栓 | SCM435 | SUSXM7 |

四氧化三鐵保護膜(黑) | ||

簧片 | SUS304 | SUS304 |

軸環 | SUS304 | SUS304 |

內六角螺栓 | SCM435 四氧化三鐵保護膜(黑) | SUSXM7 |

*也可生產陽極氧化處理。請洽詢。

適用馬達

| XBW | XBWS |

伺服馬達 | ◎ | ◎ |

步進馬達 | ◎ | ◎ |

一般常用馬達 | △ | △ |

◎:特優 ○:優 △ : 可使用

特性

| XBW | XBWS |

零背隙 | ◎ | ◎ |

高扭矩 | 〇 | 〇 |

高扭轉剛性 | ◎ | ◎ |

容許誤差調整 | 〇 | 〇 |

耐腐蝕性(全不鏽鋼) | - | ◎ |

◎:特優 ○:優

應用

線性模組/表面封裝機/精密XY軸平台/分度台

根據軸徑、常用扭矩選型

軸徑和常用扭矩交叉區域為選型規格。

選型範例

選型條件為軸徑φ15、常用扭矩2N.m時,選型規格為XBWS-34C3A

根據伺服馬達的額定輸出選型

額定輸出 (W) | 伺服馬達規格* | 選型規格 | |||

馬達軸徑 (mm) | 額定扭矩 (N· m) | 最大扭矩 (N· m) | XBW-C 鋁合金軸套 | XBWS-C 全不鏽鋼製 | |

10 | 5 - 6 | 0.032 | 0.096 | XBW-15C | XBWS-15C |

20 | 5 - 6 | 0.064 | 0.19 | XBW-15C | XBWS-15C |

30 | 5 - 7 | 0.096 | 0.29 | XBW-19C | XBWS-19C |

50 | 6 - 8 | 0.16 | 0.48 | XBW-19C | XBWS-19C |

100 | 8 | 0.32 | 0.95 | XBW-19C | XBWS-19C |

200 | 9 - 14 | 0.64 | 1.9 | XBW-27C | XBWS-34C |

400 | 14 | 1.3 | 3.8 | XBW-34C | XBWS-39C |

750 | 16 - 19 | 2.4 | 7.2 | XBW-39C | XBWS-56C |

*馬達規格為一般資料的數值。詳細資料請參閱各馬達製造商相關型錄。以上為不使用減速機等情況下的推薦尺寸。

| 型號 | 2D / 3D 檔下載 | |

|---|---|---|

| XBWS-15C2A | XBWS-15C2A.zip | |

| XBWS-19C2A | XBWS-19C2A.zip | |

| XBWS-25C2A | XBWS-25C2A.zip | |

| XBWS-27C2A | XBWS-27C2A.zip | |

| XBWS-34C3A | XBWS-34C3A.zip | |

| XBWS-39C2A | XBWS-39C2A.zip | |

| XBWS-44C2A | XBWS-44C2A.zip | |

| XBWS-56C3A | XBWS-56C3A.zip |